- Sale

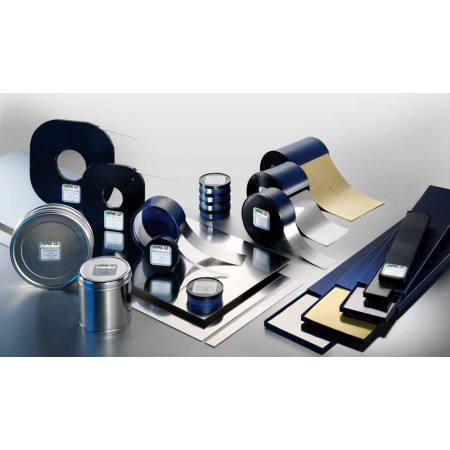

- Planchettes and AMPCO

- 3D measuring and scanning

- Grinding and polishing

- Grinding stones

- Disks

- Grinding tools

- Diamond and CBN tools

- Polishing tools

- Grinding points

- BM - corundum white

- BK - artificial white corundum

- RK - artificial pink corundum

- ARU - ruby

- CK - nobler white corundum brown

- CKK - black silicon carbide

- HK - normal corundum with resin

- HOK - corundum with an open structure

- MK - premium corundum blue

- MKL - standard corundum blue

- RKN - nobler pink corundum

- RKQ - nobler corundum dark red

- SIC - silicon carbide green

- ZK - green carbide

- CERAMIC - a mixture of ceramic grains

- Other

- Sets of grinding points

- Hand and rotary brushes

- Polishing pastes and emulsions

- Emulsions

- Abrasive pastes

- Diamond pastes

- Czech pastes, type DpP

- Japanese pastes, type DpH15

- KEMET pastes, type SP

- KEMET pastes, type SC

- KEMET pastes, type S

- KEMET pastes, type L

- KEMET pastes, type SL

- KEMET pastes, type KD

- KEMET pastes, type W

- Russian pastes, type DpR

- Lapping pastes, type AG

- Ultra-Diamant pastes, type AG

- "Super-Diamant" pastes, type AG

- Diamond powder

- Diamond spray

- Thinners

- Other grinding and polishing pastes

- Workplace equipment

- Pneumatic devices

- Equipment for the field of antistatic

- Electric and cordless devices

- Hand tools

- Milling cutters and drills

- Files

- Lubricants, greases and sprays

- Welding

- Laser welding materials

- TIG welding materials

- LASE ONE - microwelding

Description

Cold rolled, stainless spring steel from material number 1.4310.

The alloy with 17% chromium and 7% nickel has good corrosion resistance. Compared to 1.4301, it is possible to achieve significantly higher strength. Material 1.4310 is very suitable for stainless steel precision calibrated strips and base foils and stainless steel springs, as well as parts with higher strength. This material is only weakly magnetic, so it cannot be attached to magnetic clamping plates during grinding. Please note that the material 1.4310 must be during offset or bending should always be transverse to the rolling direction. When used as a flat spring, it is also necessary to take attention to the rolling direction.

Strength / hardness 1500-1700 N / mm2

AMPCO, AMPCOLOY

AMPCO, AMPCOLOY Bronze

Bronze Aluminum

Aluminum Copper

Copper Brass

Brass Stainless steel

Stainless steel Nickel

Nickel Steel

Steel Sets of base planchettes

Sets of base planchettes Grinding stones

Grinding stones Discs

Discs Grinding tools

Grinding tools Diamond and CBN tools

Diamond and CBN tools Polishing tools

Polishing tools Grinding pins

Grinding pins Hand and rotary brushes

Hand and rotary brushes Polishing pastes and emulsions

Polishing pastes and emulsions Pneumatic tools

Pneumatic tools Equipment for the field of antistatic

Equipment for the field of antistatic Electrical equipment and battery equipment

Electrical equipment and battery equipment Hand tools

Hand tools Milling cutters and drills

Milling cutters and drills Files

Files Lubricants, greases and sprays

Lubricants, greases and sprays Materials for laser welding

Materials for laser welding Materials for TIG welding

Materials for TIG welding

vibration.sk

vibration.sk